Understanding the e-axle motor technology featured in the BNC Perfetto Electric Scooter.

Coimbatore based company BNC Motors has recently unveiled its new Perfetto electric scooter. The company has been in the electric industry for the last 5 years in the electric automotive industry and is all set to capture the EV two wheeler segment with the launch of its latest scooter.

Scooter Design

The BNC Perfetto scooter is designed like a traditional scooter in the 90s, and is filled with practicality and also houses a robust and a reliable powertrain sourced from its partner Musashi.

Musashi is one of the oldest automotive component manufacturer global companies, as it has also worked with many brands like Honda, Ford, General Motors, Audi, BMW, Fiat, Triumph, JLR and more.

BNC has styled the scooter by incorporating Italian-inspired design on the Perfetto, which is also seen on Lambrettas and Vespas of the 60s and 70s.

BNC History and Significance in the Automotive Industry

The company has partnered with BNC and will be focussing towards strengthening the presence of the electric industry in India. Both the companies collaborated on R&D over three years ago, which also led to the innovation and production of e-axle for electric two-wheelers. The Perfetto is the first scooter from the BNC to feature the same technology.

BNC’s Anirudh expressed that the company was looking for a reliable yet robust technology to power their electric scooters, He further said, “When we look at the scooter segment today, it is completely a family driven segment. The scooters come in the category where both men and women will ride the same scooter in a family, mainly in the 125 cc segment,” he explains.

For a perfect family electric scooter to succeed in India, several factors are important like styling, practicality, and functionality are extremely important.

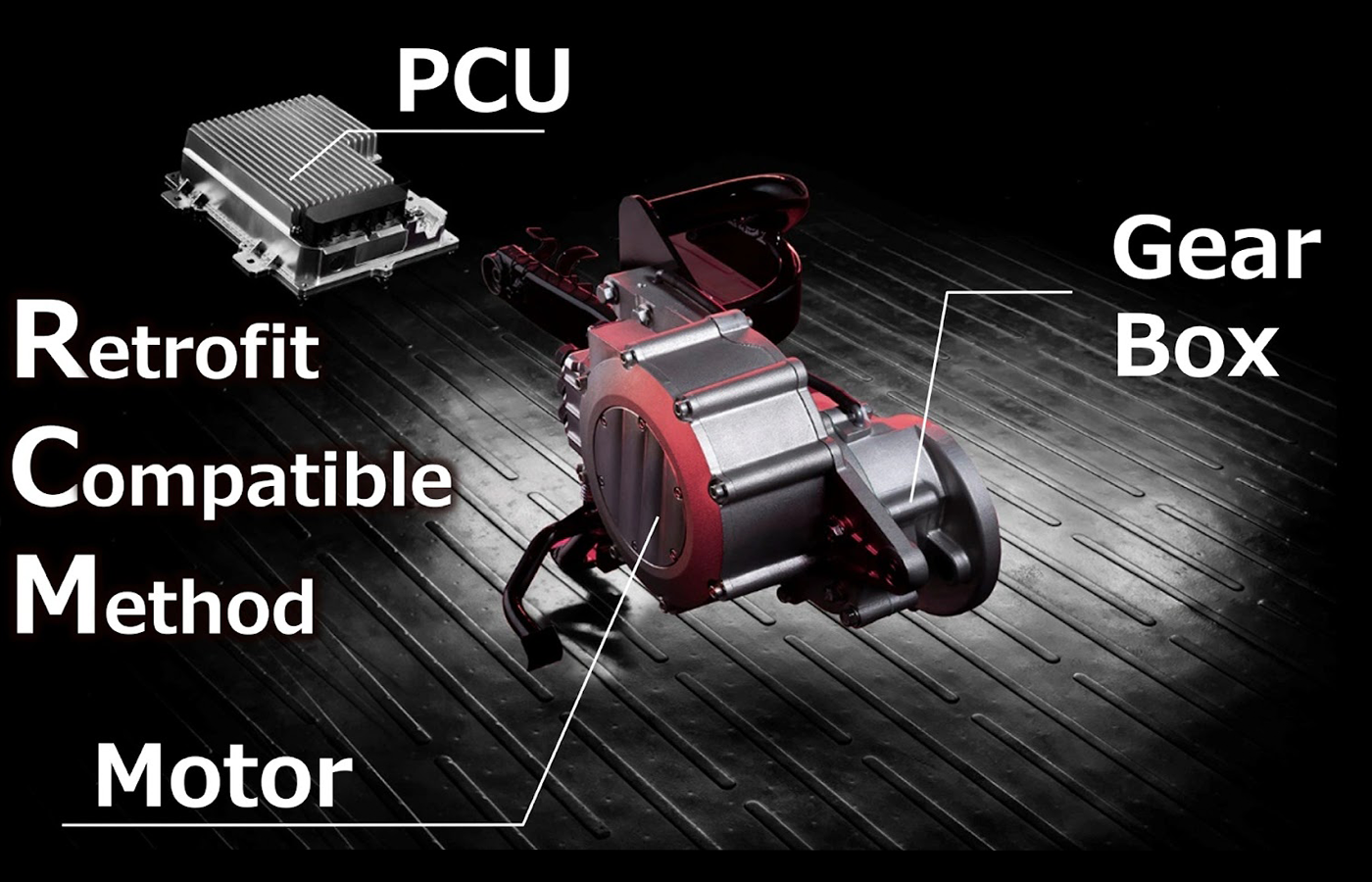

Understanding the e-Axle Motor Technology

The e-Axle technology is quite a smart technology which is specifically engineered to offer reliability. The e-Axle motor is also easy to integrate in the scooter platform as it is side-mounted, which makes it easy to fit in, as compared to hub-mounted and mid-drive motors available on the other scooters. Thus this technology has better space management without sacrificing the speed and torque of the scooter.

POWER: The e-axle motor is able to churn 80 Kmph of top speed for the BNC Perfetto, and goes from 0-40 in just 4 seconds. e-Axle has also increased the potential of the scooter by making it powerful enough to handle gradients up to 16 degrees.

The company learned about the e-axle technology by constructing multiple components for the auto sector over these years. This comprises from gearboxes to components for fuel cell electric vehicles (FCEV).

BNC has also partnered with Delta electronics in Taiwan and collaborations with Toyota Tsusho. Thus the company from these collaborations have learned the applications of e-axle motors and applied the same to its latest offering.

BNC expresses that scooters have multiple use cases to fill in India and that’s why reliability is the most important element that is need to be fitted in the scooter to make it reliable and robust. The company wants its customers to use the Perfetto in the same way as they use the other 125 cc scooters in the segment.

Vision For India

Perfetto is a well engineered product and is made with the vision of mainstream adoption in markets like India, as both BNC and Musashi have great expectations with the Perfetto. The company is also planning to export the scooter to multiple markets across the world.

BNC also exports the Challenger electric two-wheeler from its lineup and has also confirmed that they will soon launch a facelift model of the Challenger with the e-axle motor for the international markets.

The growing electric automotive industry has good business opportunities for Musashi as well. The PLI scheme and boost from the government has encouraged local manufacturing in the country. This will lead to more cost effective components for the electric motors and the battery.

Musashi and BNC are having partnerships on the batteries. BNC also has a 2,50,000 sq. ft. of manufacturing facility with the capacity to produce 15,000 units per month, it is also ready to fulfill the growing demand with extra space to expand its manufacturing capacity. BNC’s major business comes from various exports at the current time.

.webp)