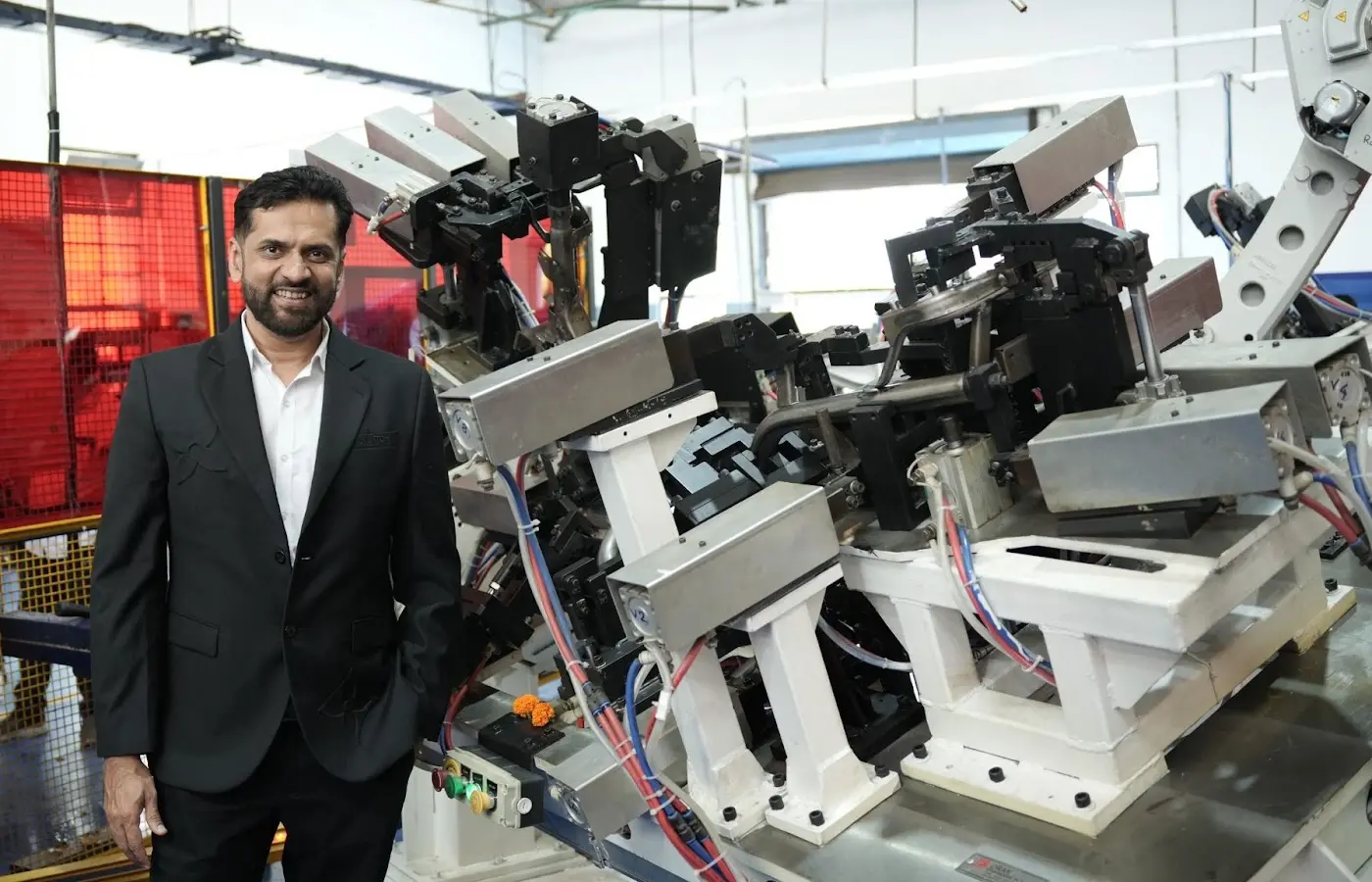

Kinetic Engineering introduces a fresh production line for robotic chassis tailored for the DX e-scooter.

Kinetic Engineering has started its state-of-the-art Robotic Chassis Line in Ahilya Nagar, Maharashtra for exclusive manufacturing of their recently launched DX electric scooter. The new Robotic Chassis line will be focussing on robotic wielding, setting up auto fixtures, and starting a specific cell for scooter framing for the DX electric scooter.

According to the manufacturer, the new robotic chassis production line is developed for ensuring sharp precision, structural accuracy and increased productivity. All this is possible, thanks to the advanced technology that reduces the scope of errors, while maintaining quality in its works.

Kinetic DX Advanced Robotic Chassis Production Line

The production facility which is working on the manufacturing of DX e-scooter has upgraded their technology and tools for high-scale production of DX e-scooter. The metal body line now features hydraulic and mechanical presses, spot wielding guns, and pneumatic clamping fixtures which enhances the efficiency and precision in panel fabrication.

.webp)

The production line has also upgraded the paint shop by starting body and frame painting, in order to ensure a greater quality of paints on the electric scooter, 7-tank process with CED coating, which is integrated with metallic top coating which provides better protection against corrosion, ensuring a premium quality for its users.

There are also various manufacturing facilities available such as exclusive stores focussing on frame child parts following receipt quality systems, individual gauges set for every part, and also an inclusion of kid-based supply specifically for fulfilling the requirements of sub-assembly.

This new and advanced technological approach for Kinetic will effectively optimize their inventory management and maintain the quality by smooth and efficient operations.

.webp)

The Vice Chairman and Managing Director of Kinetic Engineering expressed his views on the new robotic chassis line, and said, “The future of manufacturing will be led by only those companies which can effectively integrate automation, precision, while maintaining sustainability in their overall operations.

With our completely new Robotic Chassis line in place, we are not only updating our manufacturing facility but we are innovating how manufacturing can be implemented in India from advanced practices. This strategic move has helped us to deliver consistency by ensuring reliability. In future our ways will set a benchmark for how innovation in manufacturing can transform traditional industries.

Thus Kinetic has played a major role in transforming Indian manufacturing by competing with the best industries in the world.

.webp)